6 FAQ you should know about Industrial Raspberry PI

April 7, 2022

How an Industrial Raspberry Pi gateway combined with Codesys to solve 3 major challenges in IIOT

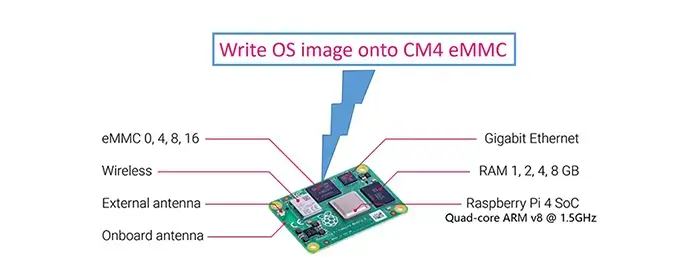

June 23, 2022Elastel EG500 is an industrial Edge computing Gateway designed for IoT applications. Powered by Raspberry Pi CM4 featured high-performance edge computing capabilities. It supports 6 DI, 6 DO, and 3 AI. With elastic network connectivity, which makes it allows communicate with all common analog and digital sensors, actuators, and bus systems, as well as TCP-IP based network equipments.

Benefit from powerful Raspberry Pi OS compatibility, This is huge potential, you can run almost anything on EG500, which generate multiple features for versatile solutions.

In contrast to classic programmable logic controllers (PLCs), soft PLCs do not have a single predefined software for programming. Instead, the industrial Raspberry Pi can be programmed in almost all languages, from high-level languages (eg C, C#, Java, PHP, Python), to classic automation solutions (eg Codesys) or graphical tools (eg NodeRed).

In this paper, we will propose five possible applications scenarios.

- Industrial raspberry PI as ERP/BDE/PPS data supply source

This Solution allows you to access system data. You can use an industrial Raspberry Pi as a system controller, use it and various sensors for low-cost system retrofits, or read data from existing PLCs via Profinet, ModBus RTU or OPC-UA.

If necessary, the data can also be processed on the industrial Raspberry Pi before forwarding it to an ERP system (such as SAP or MS Dynamics Nav), a production data acquisition system (BDE) or a production planning and control system (PPS).

Variety of programming languages and most software solutions provide ready-made libraries and interfaces for REST, XML, JSON, and Excel and CSV exports. Moreover, the data can run in both directions. ERP or PPS order data can also be obtained directly from the industrial raspberry PI

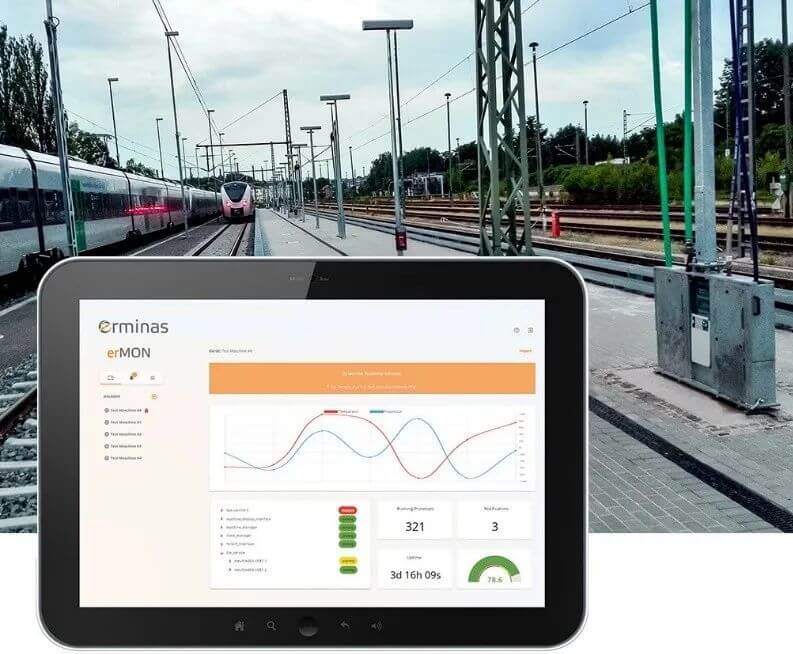

2. Industrial raspberry PI in modern system monitoring

The system must continue to operate stably, and technicians must respond quickly if something goes wrong. Especially in the case of outdoor systems, it is often difficult for operators to arrive quickly and report faults in a timely and accurate manner. In such cases, you can connect the industrial Raspberry Pi to an existing network or through a router, which can be used to monitor the system.

You can use any kinds of monitoring software available for Linux. Alternatively, you can choose to send data to the cloud via an industrial Raspberry Pi. In this way, you can view system status, fault history and statistics anytime on your PC browser or smartphone APP.

You can also choose to receive alerts via SMS, email, fax, etc., So that every failure can be quickly identified and resolved quickly.

3. Industrial Raspberry Pi as an edge gateway

For many companies, not every data center location has IT staff. However, data needs to be collected from these systems and then evaluated on the company’s own servers or cloud solutions.

In this case, the Industrial Raspberry Pi also offers a solution: Via OPC-UA, ModBus, Profibus, Profinet, CANbus, etc., the EG500 as an edge gateway can collect all data from the system. Data can also be securely cached, preprocessed or transformed if required, and then forwarded over the Internet to your own server or cloud solution.

The advantage of an Industrial Raspberry Pi (more precisely, the Raspberry Pi Compute Module 4) is the technical foundation of the Industrial Raspberry Pi. Since the Raspberry Pi ecosystem has countless free software libraries for data conversion, and some well-known cloud providers provide Raspberry Pi interfaces and tutorials that can be used directly on the industrial Raspberry Pi.

4. Connect your system data to applications with the help of industrial Raspberry Pi

What if your industrial Raspberry Pi system had control applications for tablets and smartphones, and the system’s HMI (Human Machine Interface) ran in a browser?

Your customers will be able to securely access system data from anywhere. And your service team will have real-time access to the system, view error logs and use remote analysis, the Industrial Raspberry Pi helps you implement a complete IIoT product line.

5. Industrial Raspberry Pi as a digital twin of the system

When a production facility is put into operation, it can only be tested and expanded to a limited scope. If the control program has to be updated or expanded, the system will be shut down or left open. And what exactly you can test depends on the production environment.

From a PLC perspective, a machine consists of input signals. With the Industrial Raspberry Pi you can record digital and analog inputs as well as inputs from many bus systems. You can create a logging library for various system operating environments, or log error conditions on a running system.

Industrial Raspberry Pi can not only record data, but also reproduce data for your PLC. You no longer need to develop on the machine, you can develop conveniently and efficiently in the office, and reproduce as many system operating environments as possible. You can also download records remotely from production to reproduce and analyze reported bugs.