5 Applications of industrial Raspberry Pi usages as a soft PLC

April 20, 2022Q1: What is the difference between an industrial raspberry PI and a consumer raspberry PI?

A1: Take the Elastel IoT Gateway EG500 series as an example of industrial Raspberry Pi. The differences between them are mainly as follows:

- The most characteristic of industrial raspberry PI is that it has passed the industrial packaging, wide temperature, using temperature from -40 to +75℃, IP20 protection grade, and has passed the industrial standard test (EN61121-2 and IEC 61000-6-2), such as EMI, surge and emergency test, as well as ESD polarity protection To 4 kv / 8 kv. It is itself a housing protection for industrial use.

- Support common interfaces for Internet of Things, such as RS232, RS485, DI, DO, ADC, strong scalability, in line with industrial requirements. Aluminum alloy housing, DIN rail mounting, a variety of RAM eMMC combination is easy to change according to demands, in the industrial situation is very convenient to use.

- Industrial Raspberry PI installed Rasbian system based on LINUX and installed real-time patches. It is a real-time system with some internal software integration and a convenient webUI configuration interface.

- Industrial raspberry PI uses 24V power supply commonly used in industry, which is more stable and equipped with load protection, etc.

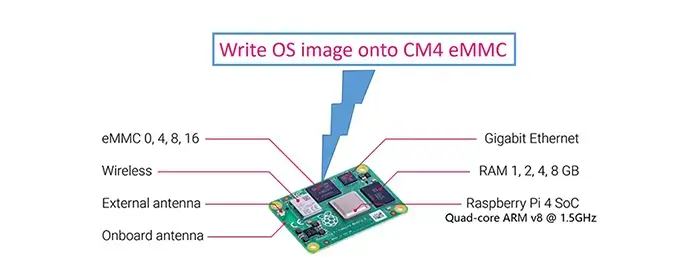

Q2: What about the specification of your industrial raspberry PI?

A2: The core spec of raspberry Pi on Elastel products is consistent with that of our consumer raspberry PI, and the core of the computing module is completely consistent with that of Broadcom CPU. The raspberry PI generation 4 is BCM2711, and QUAD-Core A72 (ARM V8)@ 1.5ghz. For the RAM, there are 1GB, 2GB, 4GB options, and for storage, there are 8GB, 16GB, and 32GB versions to choose from on flash eMMC.

Q3. How does the industrial raspberry PI perform in terms of heat dissipation? How long is the average trouble-free working time?

A3: The operating temperature of industrial raspberry PI ranges from -25 ℃ to 75℃ Compared with consumer raspberry PI, EG500 Industrial Raspberry Pi has optimized many ways. The industrial raspberry PI may not run at full speed at 65℃, so it will be optimized to reduce the frequency. In addition, the design of the industrial Raspberry PI enclosure takes heat dissipation into account. The entire aluminum alloy enclosure acts as a big heat sink. The horizontal installation ensures that air can flow up the EG500 computing module and cool the electronics (chimney effect). In addition, we can also adopt measures such as installing fans or water cooling in the control cabinet. Or for higher heat dissipation requirements, Elastel can also provide OEM customized design.

For MTBF, we have the specific test data here, and the data are different with different models in different test environments: EG500 can work for 59 years in an environment of 50℃ and 23 years in an environment of 65℃; The ElastBox400t module has been operating at 50℃ for 36 years and 65℃ for 17 years.

Q4: What are the main usage of industrial raspberry PI?

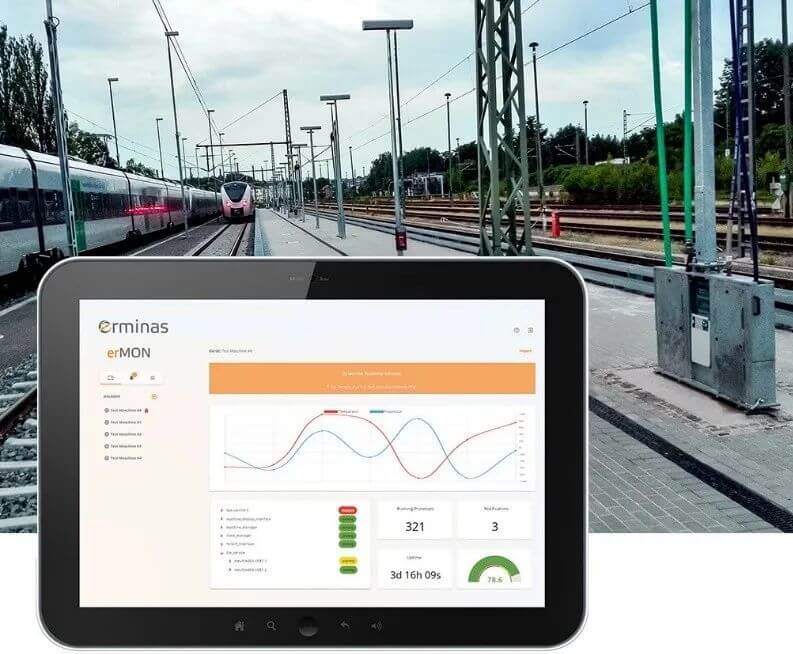

A4: Industrial raspberry pi with its characteristics of open source is widely used in various fields of industry, the current industrial raspberry pi applications upload more field data collection, small control, combining with the software used for soft PLC, industrial iot gateway, also can do some of the applications of edge computing, etc., have infinite possibility in the industrial field, we are trying to enrich and develop more applications.

Q5: How is your industrial raspberry PI PLC realized?

A5: Industrial raspberry PI is combined with third-party software to be used as PLC, such as Codesys, LogiCAD and other software, which is essentially a soft PLC function. The capability of installing third-party software Runtime in our industrial Raspberry PI and configuring it on the software to enable it to run soft PLC can be used as EtherCAT, Host of Ethernet/IP, CANopen and other protocols.

Q6: How does industrial raspberry PI collect and acquire industrial field data?

A6: This is mainly from the following aspects:

- First, the industrial raspberry PI itself can expand some IO modules, like EG500 has 1x RS232, 1x RS485, 6x DI, 6x DO, 3x AI. It directly collect some serial data, digital and analog data from slave devices;

- Second, the industrial raspberry PI itself has the function of Modbus, which can act as the master/slave station of Modbus RTU and TCP, and can collect Modbus data.

- Third, the industrial raspberry pi extensible the gateway module series, contains some of the mainstream fieldbus and industrial Ethernet, Profibus, CANopen, Profinet, Ethernet/IP, EtherCAT, etc., can be through the gateway acquisition of various industrial field control layer network data.